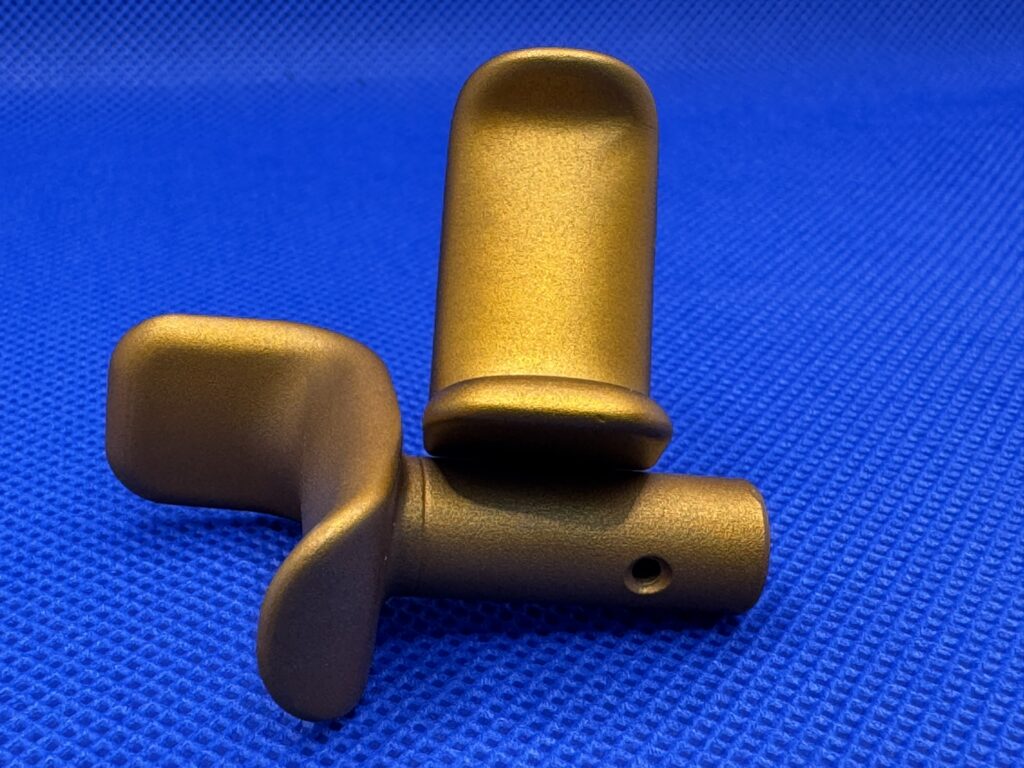

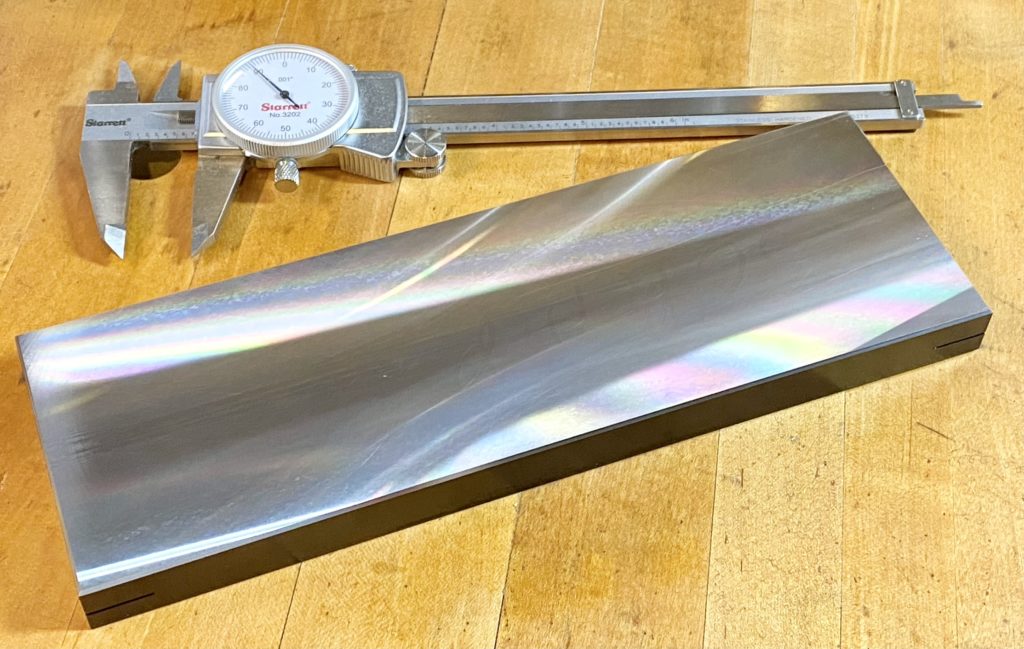

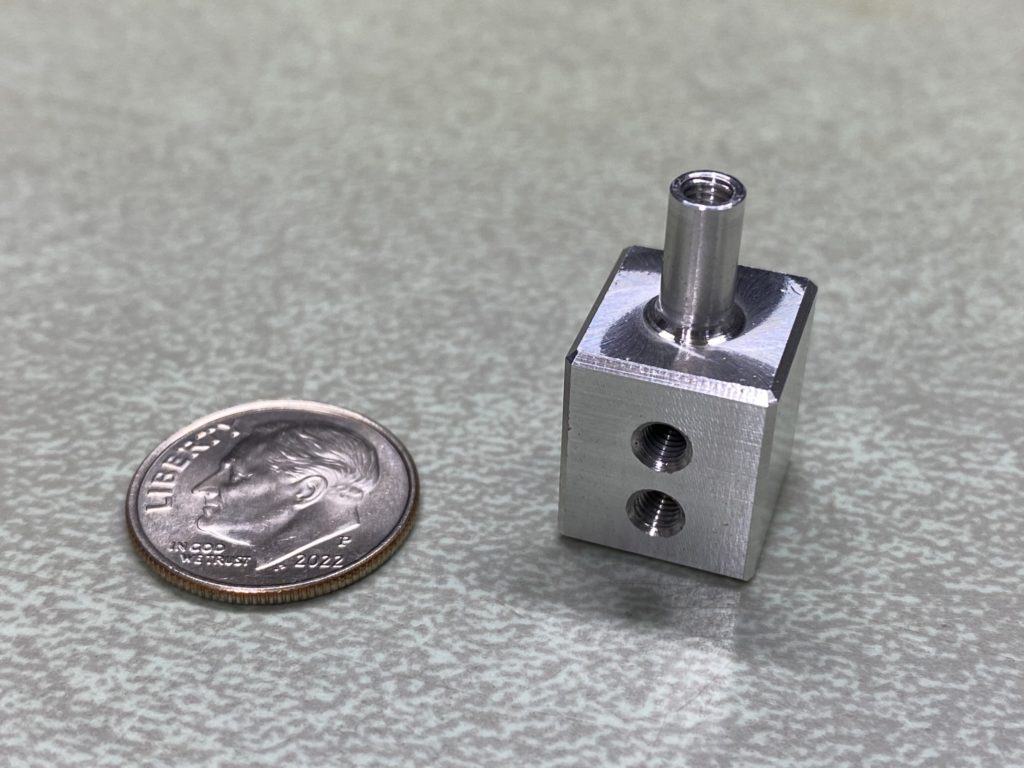

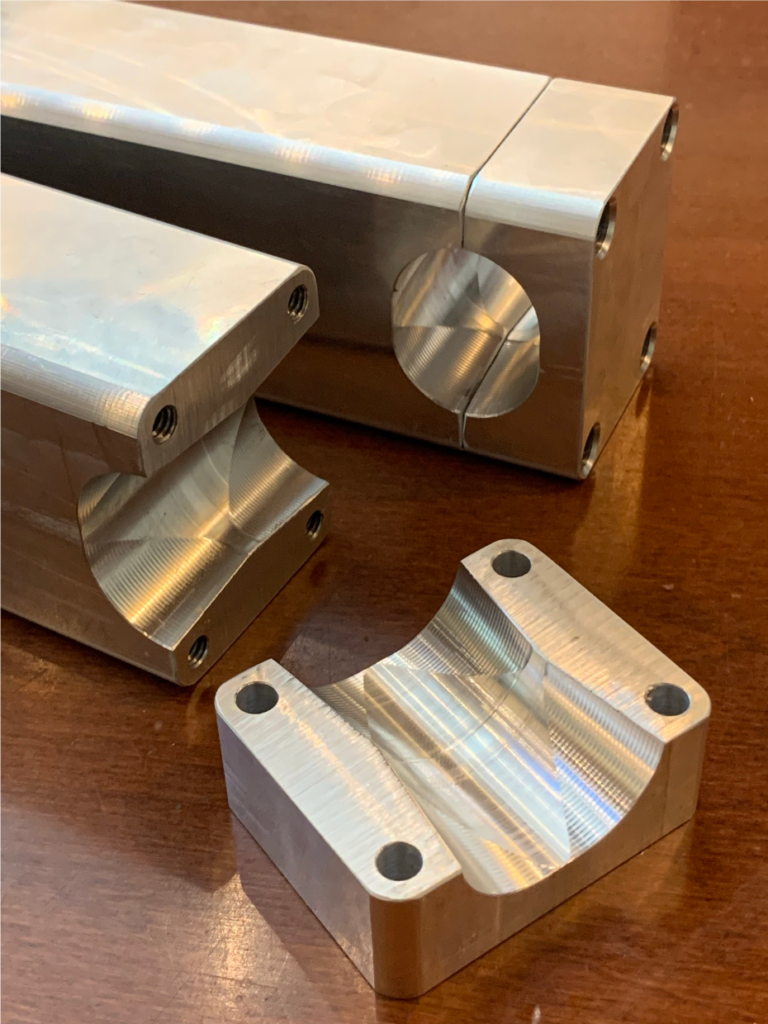

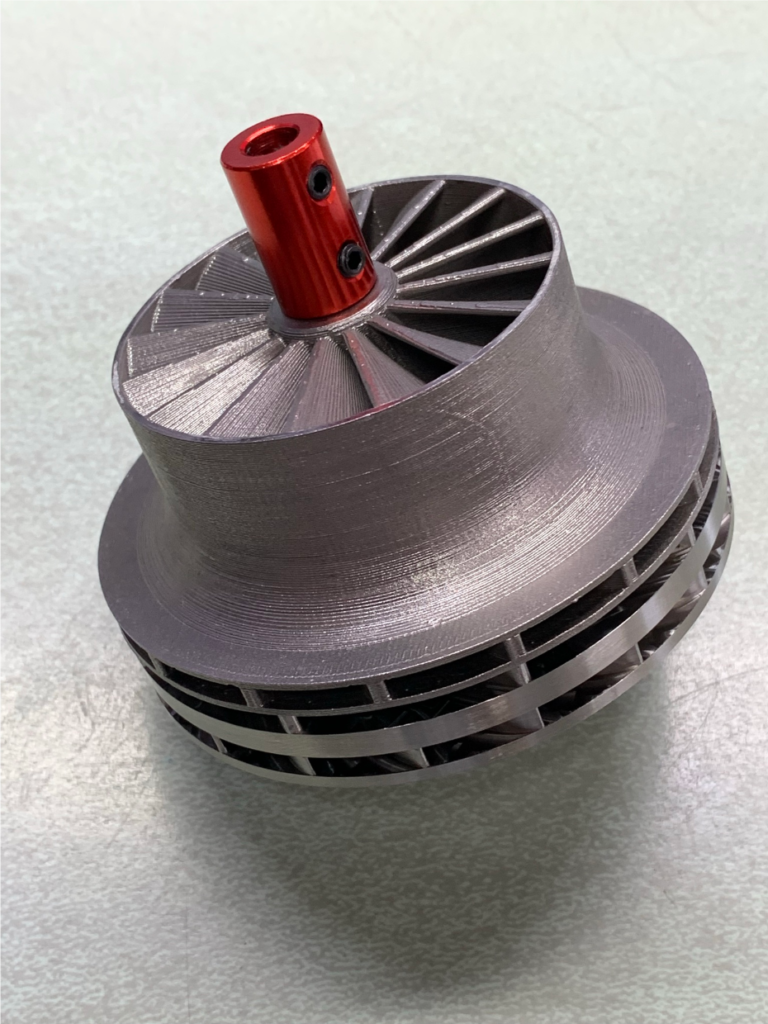

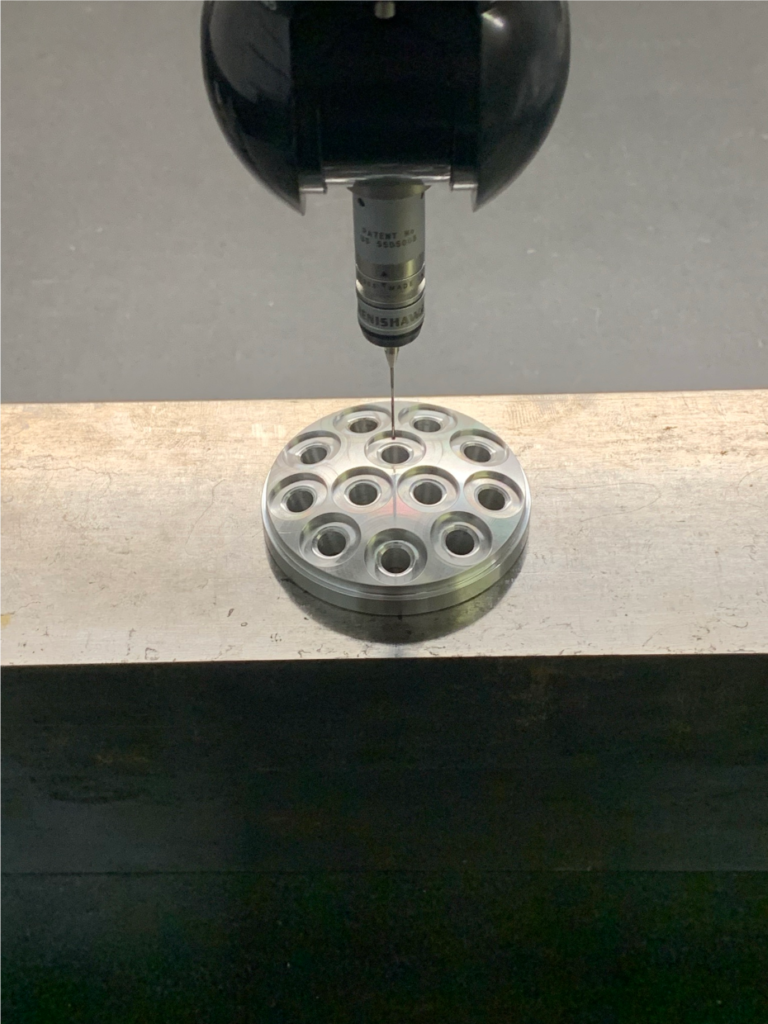

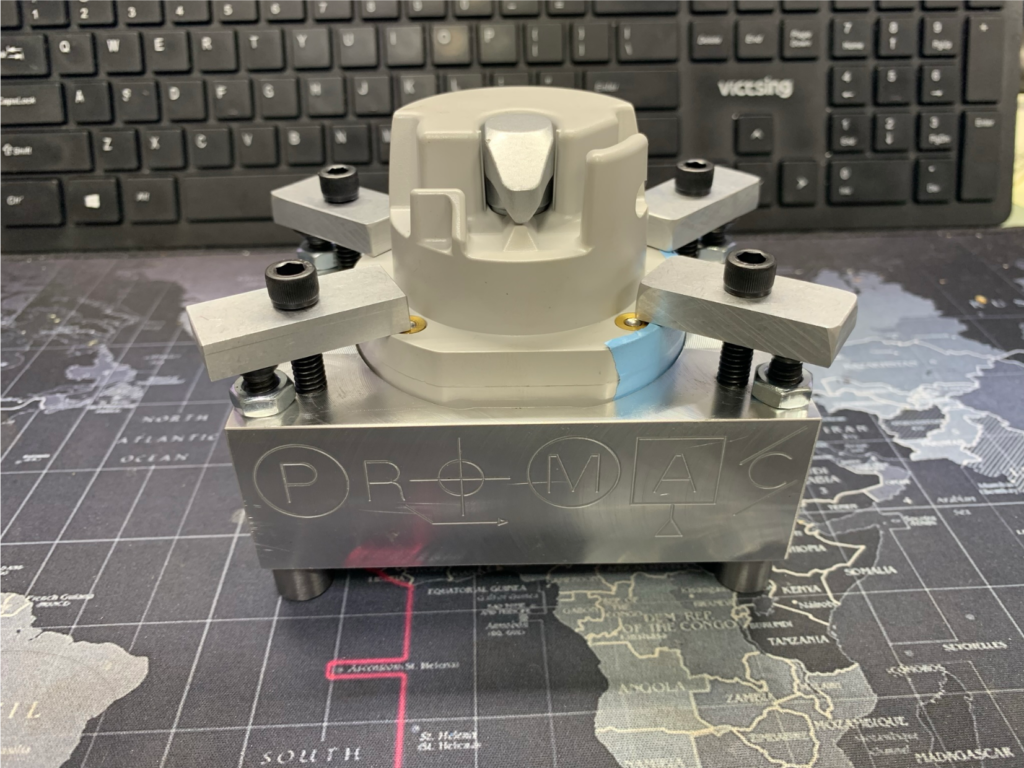

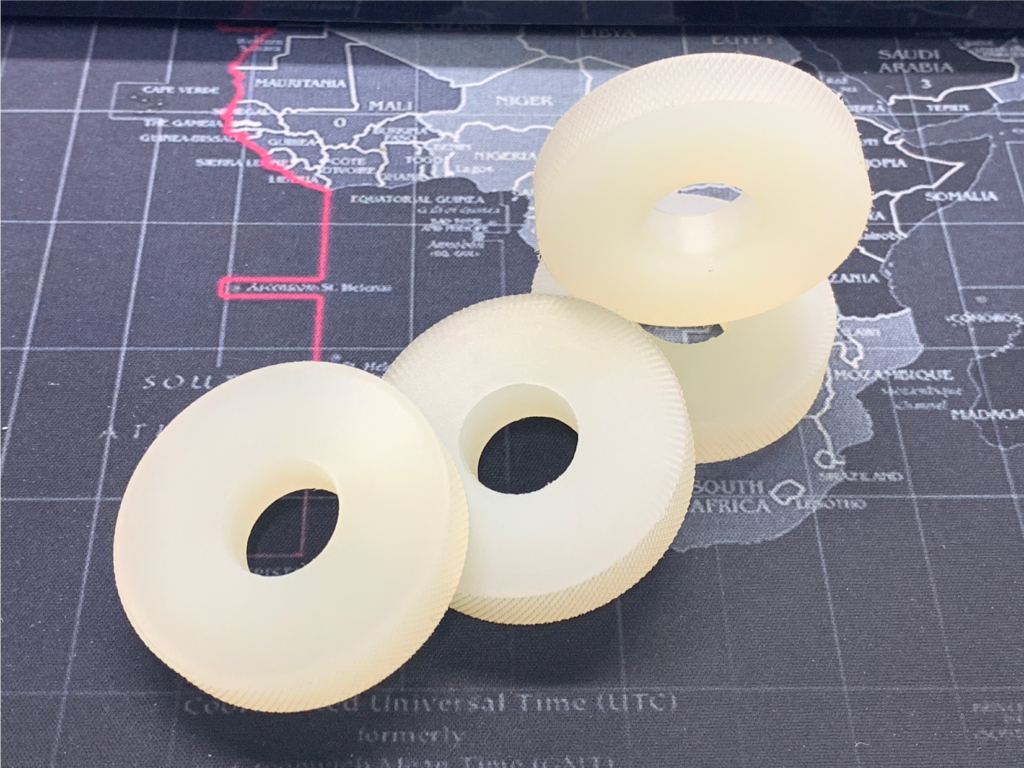

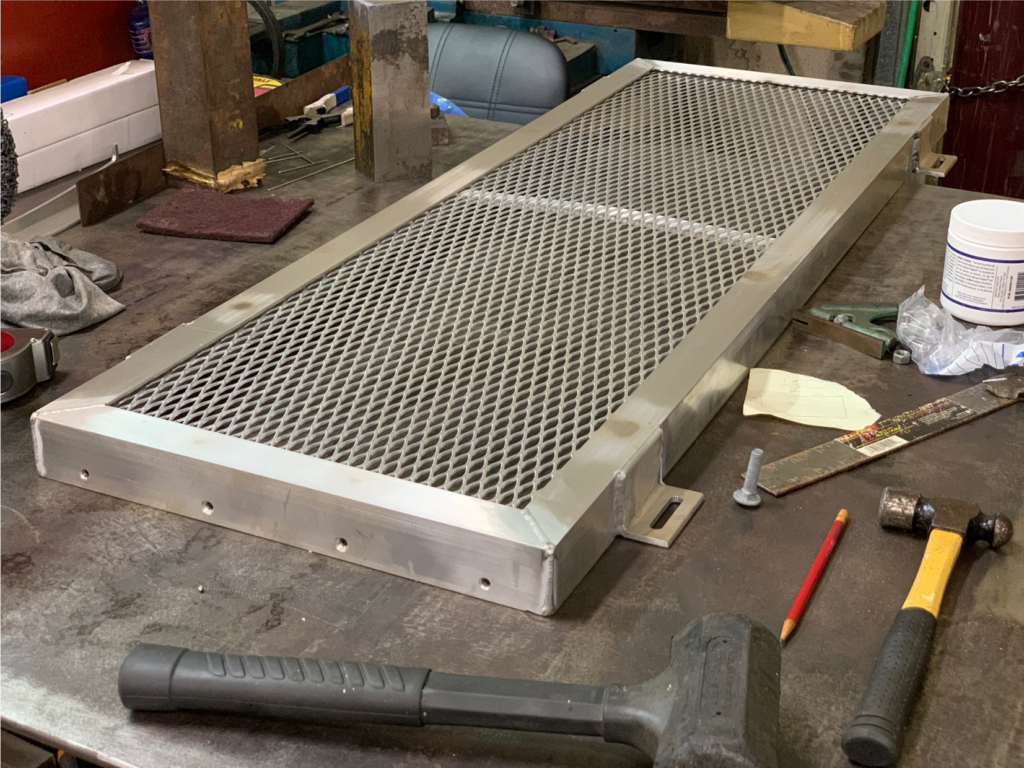

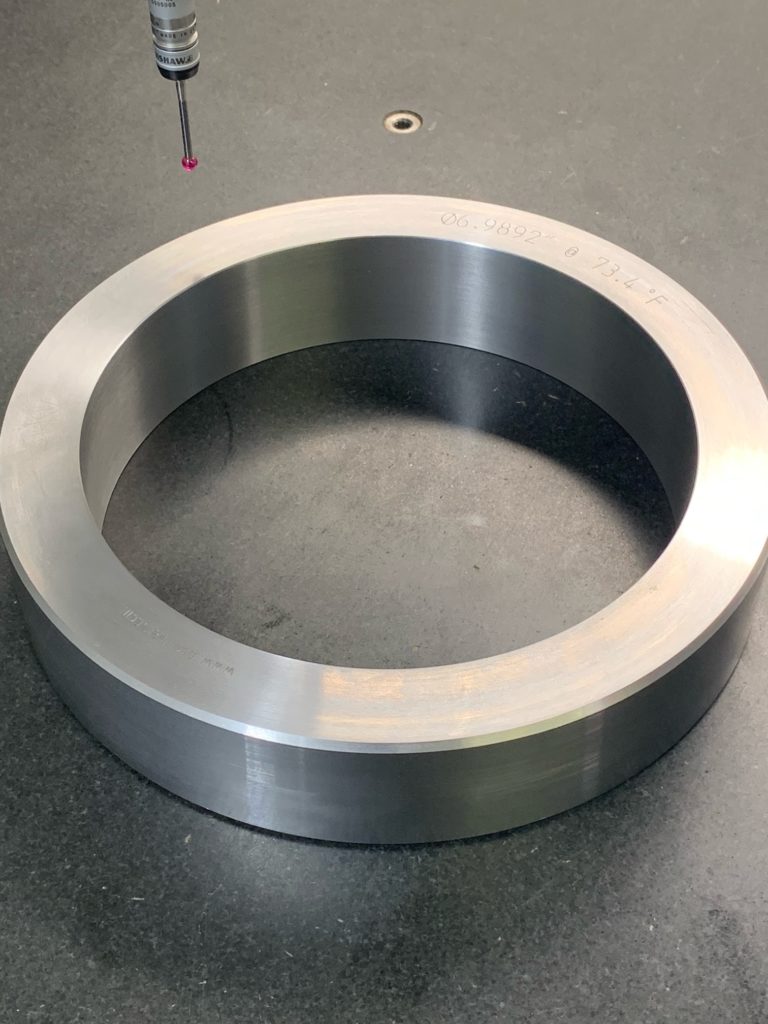

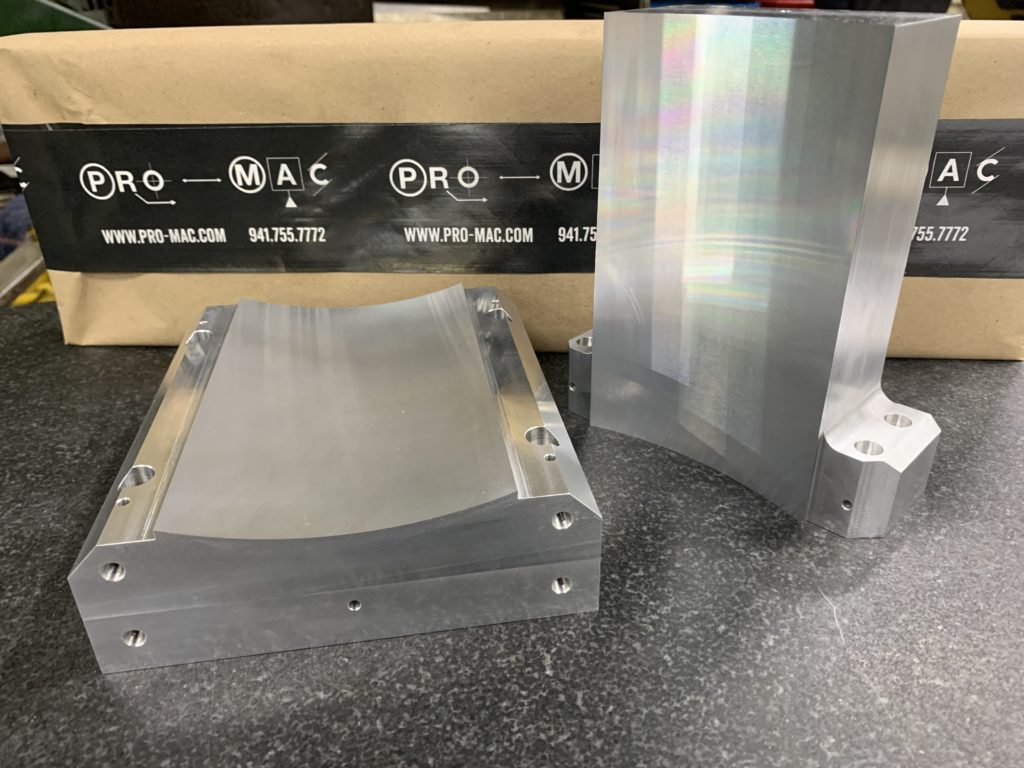

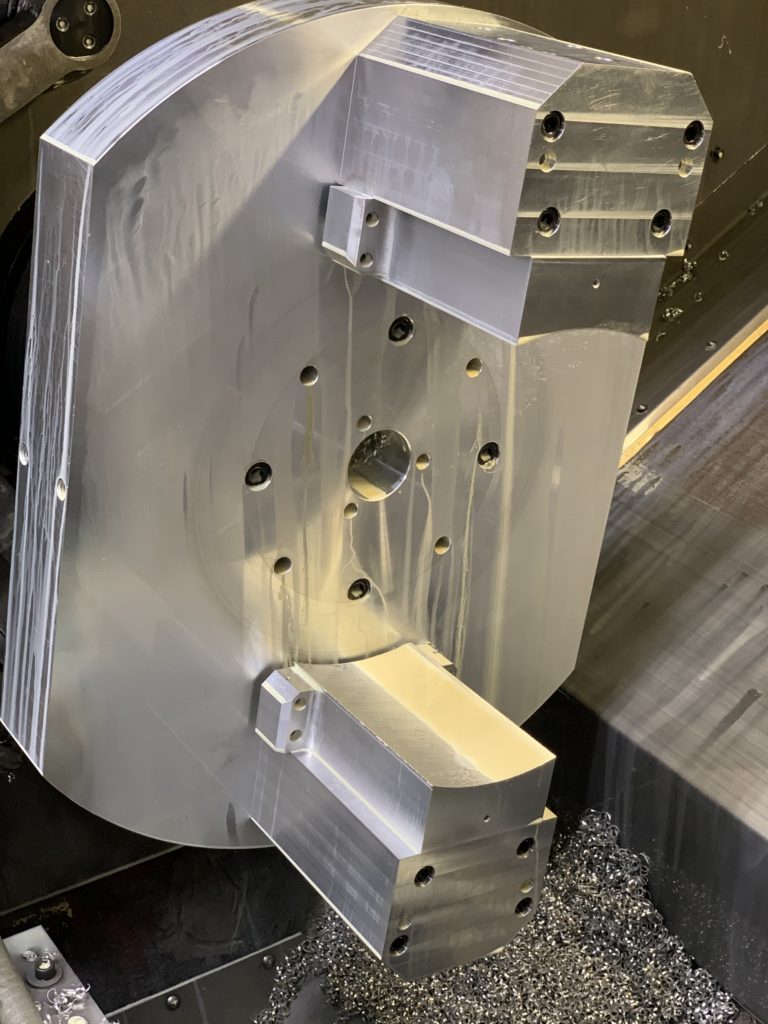

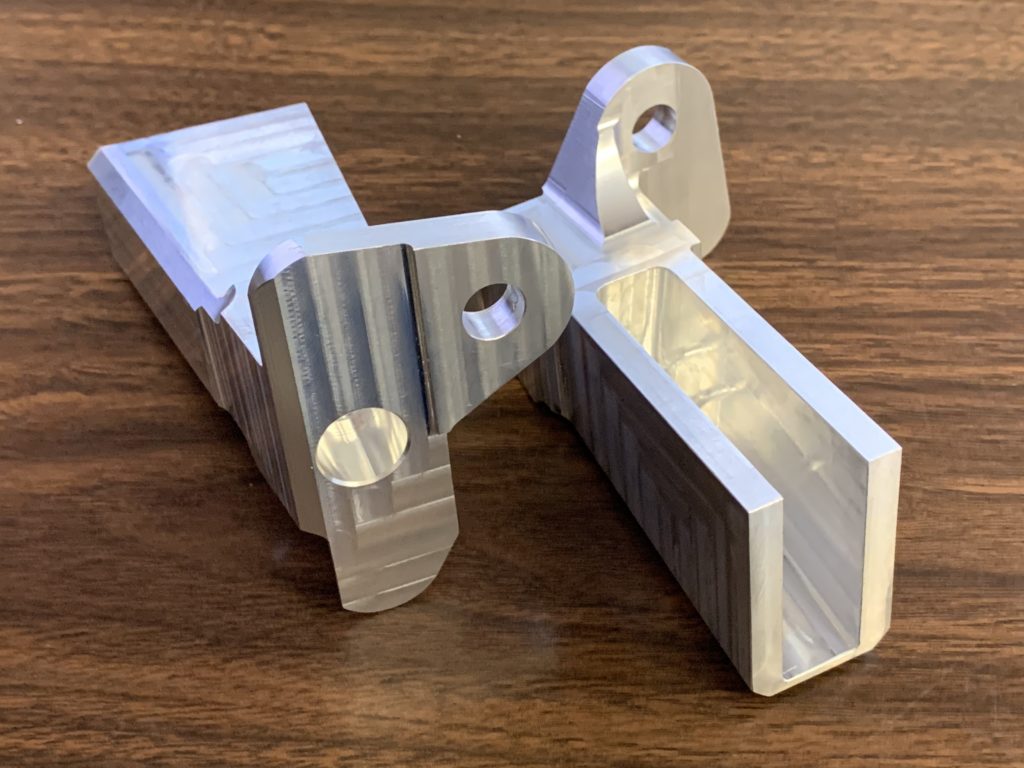

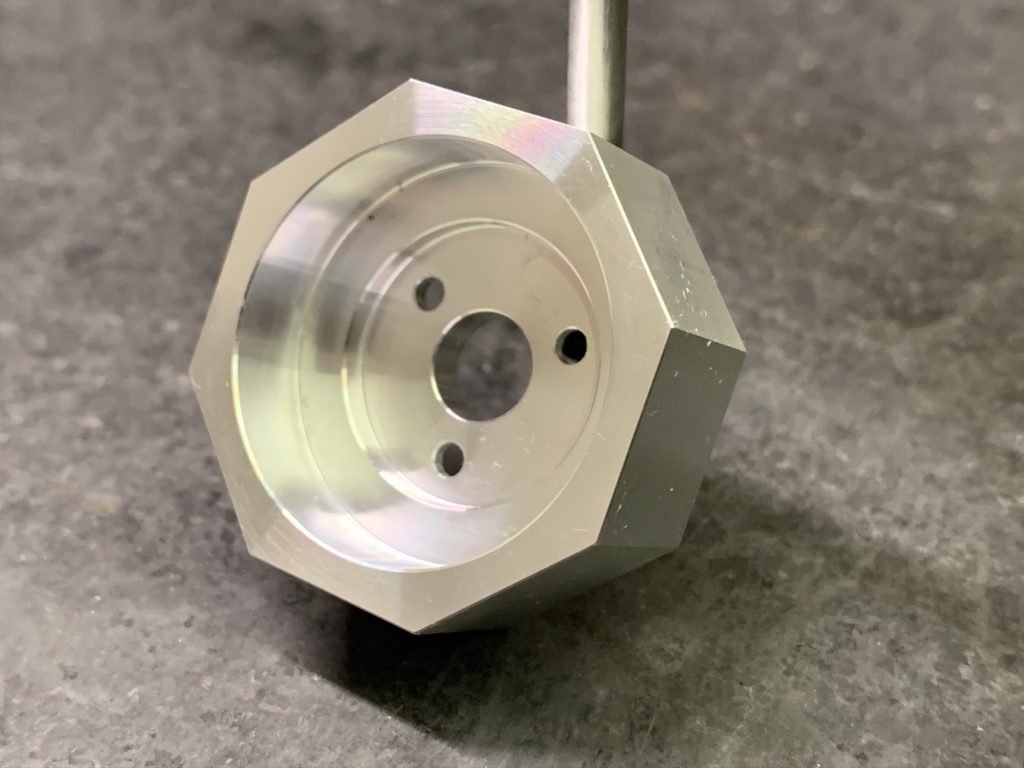

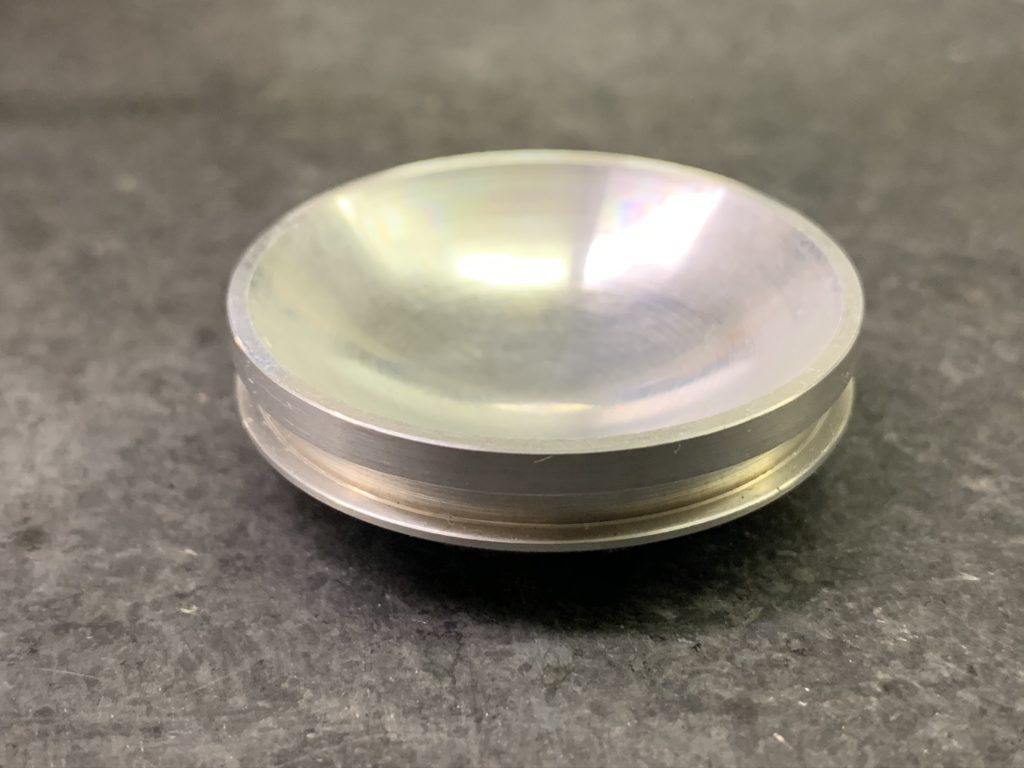

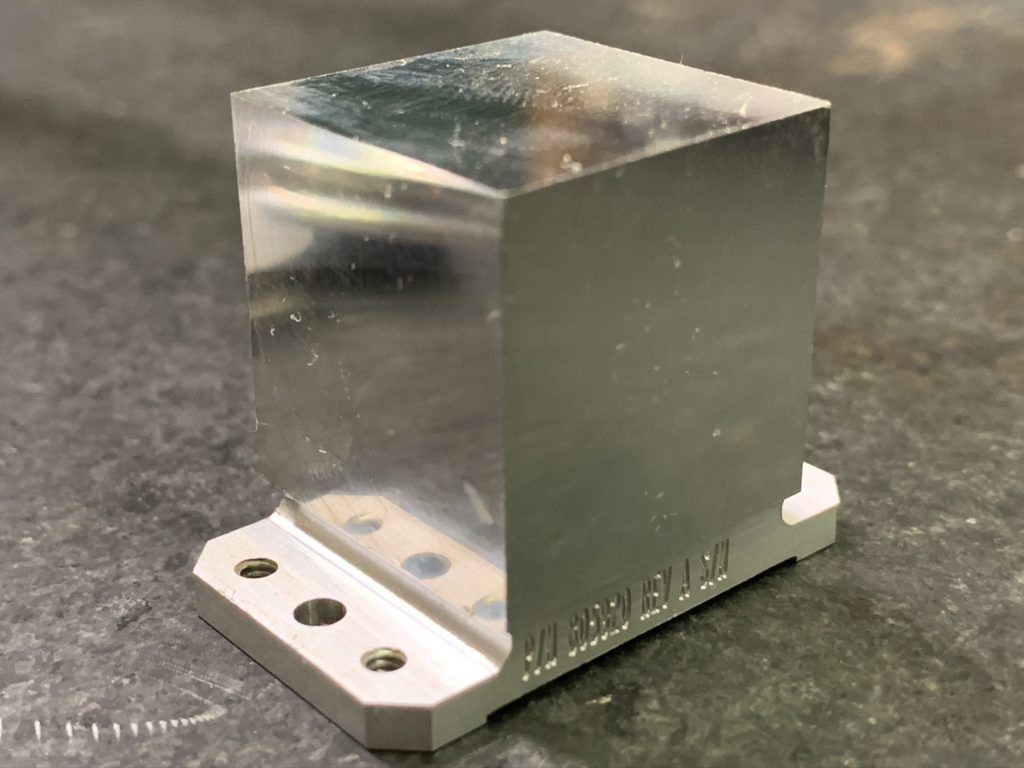

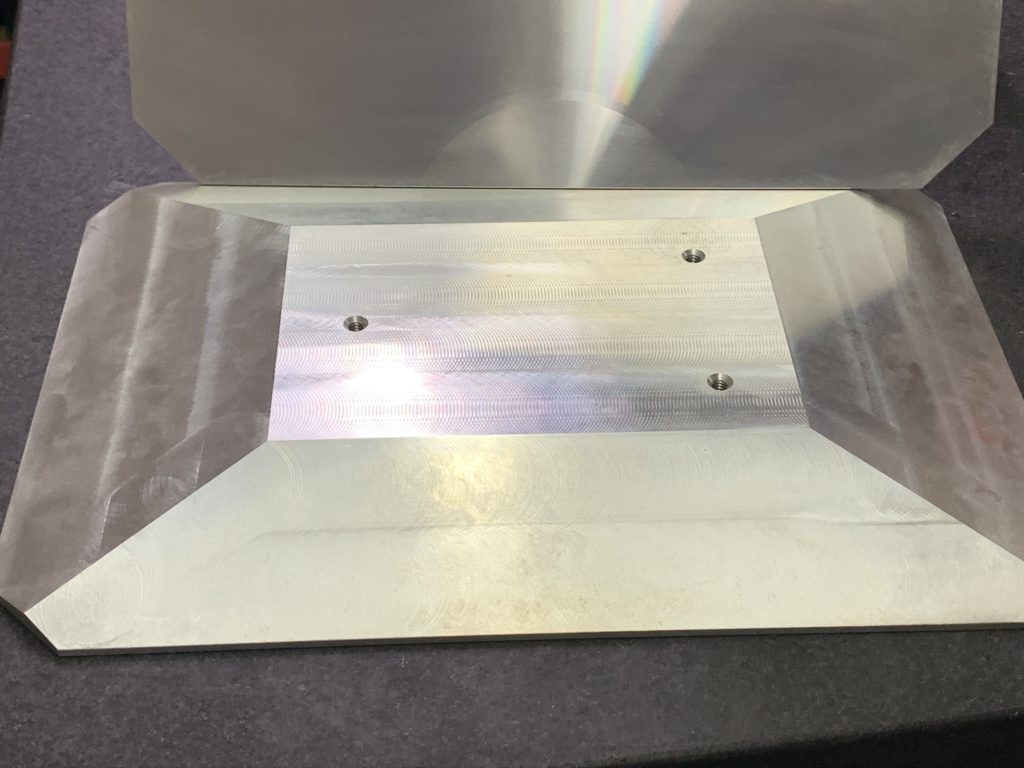

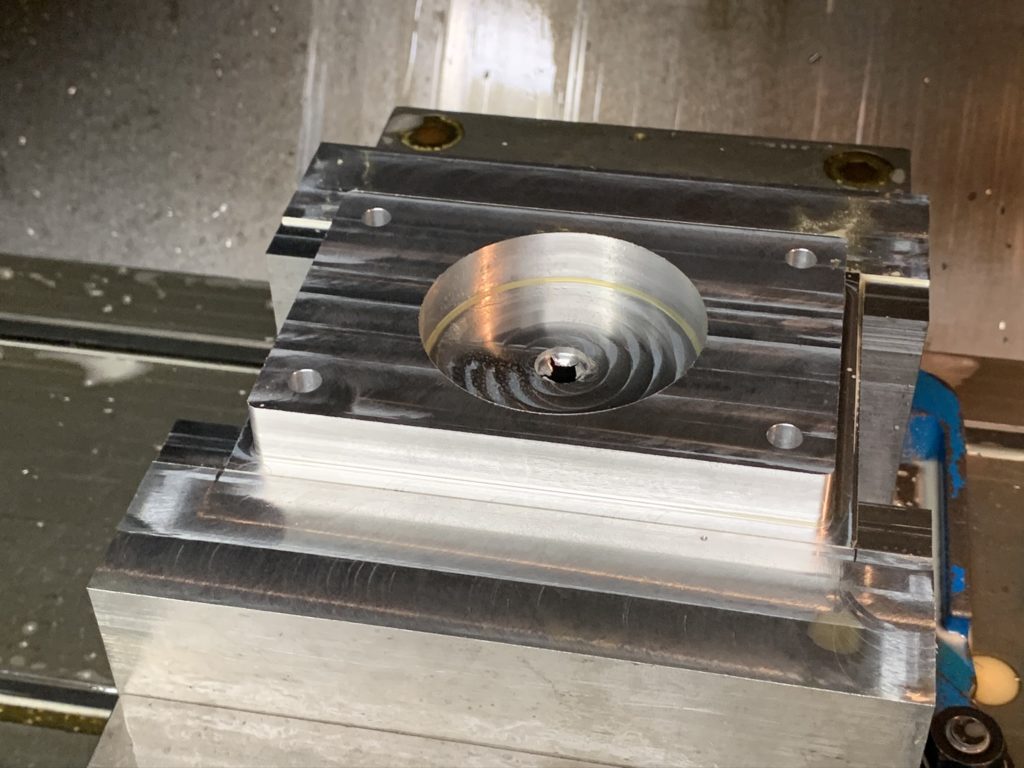

Professional Machinists Making Quality Parts

Machining Aluminum, Beryllium, Tungsten, Steel (all varieties), Plastics (Teflon, Delrin, ESD, etc.), Brass, Bronze, Copper, and much more.

Or, Contact Us

Give us a call, email, or a text. We’re happy to quote your project, no matter the size or complexity.

Call or text us at 941-755-7772

Pro-Mac Machine, 6156 15th St E, Bradenton, FL 34203

Steelhorn Innovations and Pro-Mac Machine are one and the same entity. In 2020, Steelhorn Innovations was formed by the current owners in order to acquire Pro-Mac Machine, Inc. While our legal name remains Steelhorn Innovations, we operate under the business name “Pro-Mac Machine.” Steelhorn Innovations is not a parent company with multiple holdings; it’s simply our original name coexisting with the business name Pro-Mac Machine. We appreciate your continued support and look forward to serving you with the same dedication and quality that defines our company.